Over the course of the last few Revit MEP projects I have been able to use the information in the models to calculate flows which has assisted with sizing duct and pipe. This has made the process more productive and eliminates the need to calculate everything on paper. It has also made it easier to adapt to changes as the design process evolves. I will advise that this works well on simple projects. It can get challenging when applying to more complex designs. This information is intended to show the capabilities of using Revit MEP for these calculations. An intermediate understanding of Revit MEP and some extra training is recommended.

How It Works:

Revit MEP is doing these calculations based off the properties in the duct and pipe connectors within the families. The connectors have System Type properties for Supply Air, Return Air, Exhaust Air, Hydronic Supply, Hydronic Return, Domestic Cold Water, Domestic Hot Water and Sanitary systems. Depending on the system type and flow stream, the connectors are set up in different ways to calculate CFM, Fixture Units & GPM.

Lessons Learned:

· Everything must be connected. No exceptions!

· Depending on the source of the Revit MEP family, the connectors might need to be edited in order to calculate accurately.

· Some of the plumbing fixture families may be in the architect’s model. For this reason I have created connector placeholder families with parameters for Cold Water Fixture Units, Hot Water Fixture Units, Waste Fixture Units and Diameter of pipe. Ideally these should be set up at the beginning of the project to match the Plumbing Fixture Schedule and the fixture load based on the IPC.

· Hot Water Circulation systems are not currently available in Revit MEP. I used a separate Domestic Hot Water system for the Hot Water Circulation. I did this by creating a Domestic Hot Water connector with 0 flow on one side. On the other side is Domestic Hot Water with an input for HWC flow.

· Vent systems are not currently in Revit MEP. I used a separate Santiary system which calculates waste fixture units for the Vents. I did this by creating a sanitary connector with 0 fixture units on one side. On the other side is a sanitary connector with an input for Vent fixture units. Vent lengths will need to be manually added up for sizing.

· Duct, Hydronic and Domestic Water systems need to be closed. Any open ends need to be capped.

· Sanitary & Vent systems need to have one open end. The open end is typically the pipe leaving the building.

· Creating information schedules has been a great way to manage the parameters in the families.

· Some scenarios need to be calculated manually. For example, complex duct and piping in a mechanical room.

· These systems have proven to be accurate and easy to troubleshoot. For example, if you click on a duct or a pipe and the flow is 0 that means something is not connected or there is an opening in the system somewhere.

Calculating CFM’s and Sizing Duct:

The CFM airflows are entered into the supply diffusers and all the duct is connected back to the terminal unit. Revit MEP calculates the CFM’s all the way thru the duct back to the VAV Unit. You can click on a duct anywhere in the system and see the calculated airflow (See Figure 01). It can then calculate the total airflows between the terminal unit systems and the Air Handling Unit.

Figure 01: Duct Air Flows

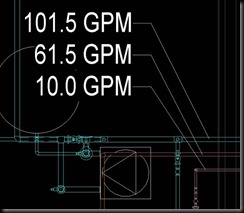

Calculating GPM and Sizing Hydronic Pipe:

The GPM’s are entered into the terminal units using a simple information schedule (See Figure 02). Revit MEP calculates the GPM all the way thru the pipe back to the Mechanical Room. You can click on a pipe anywhere in the system and see the calculated GPM (See Figure 03). If a GPM changes on a unit you can go to the schedule and change the flow. Then go back to the model, view the calculated GPM and change the size if necessary.

Figure 02: Hydronic Flow Schedule

Figure 03: Hydronic Pipe Flows

Calculating Fixture Units/ GPM for Sizing Domestic Water Pipe:

Revit MEP will do the conversion from Fixture Units to GPM using the values from the 2006 International Plumbing Code (IPC). It does this for both Flush Tank and Flush Valve systems. This will work for Domestic Cold Water and Domestic Hot Water systems.

Note: I created a separate Domestic Hot Water system for the Hot Water Circulation since Revit MEP does not currently have a system type for HWC.

The GPM totals shown are calculated from all the Fixture Units in the building. From top to bottom: CW, HW, HWC (See Figure 04).

Figure 04: Mechanical Room Domestic Water Flows

You can click on a pipe anywhere in the system and see the calculated Fixture Units and GPM. If a fixture is removed or you have to re-route piping you can view the calculated GPM and change the size as necessary. Here you can see the Fixture Units [86.5] being converted to (63.2) GPM using Predominantly Flush Valves (see Figure 05).

Figure 05: Domestic Cold Water Flows

Calculating Fixture Units for Sizing Sanitary & Vent Pipe:

Revit MEP will calculate Fixture Units thru sanitary pipe based on the Fixture Units assigned to each fixture family. The total Fixture Units in the Sanitary pipe leaving the building are calculated. Revit MEP automatically calculates the Fixture Units all the way thru the pipe to the open end leaving the building (See Figure 06).

Figure 06: Total Sanitary Fixture Units

You can click on a pipe anywhere in the system and see the calculated Fixture Units. If a Fixture Unit changes on a fixture or you have to re-route piping you can view the calculated Fixture Units and change the size as necessary. There are 93 total Waste Fixture Units for this bathroom (See Figure 07). The same applies to the vents for this bathroom (See Figure 08).

Note: I created separate Sanitary systems for the Vents since revit does not currently have a system type for Vents.

Figure 07: Bathroom Sanitary Fixture Units

Figure 08: Bathroom Vent Fixture Units

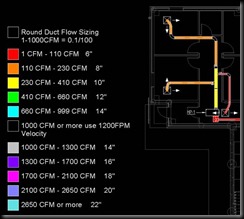

Duct & Pipe Flow Legends:

I set up a view with a Duct Legend. It is an editable legend that can be set up to apply colors to ducts based on the flow. I was able to use this to help size duct based off the flows calculated from a Ductulator (See Figure 09).

Figure 09: Duct Flow Legend

I set up a view with a Pipe Legend. I was able to use this to help size pipe based off the 2006 International Plumbing Code Figure E103.3(3) Friction Loss in Smooth Pipe. (See Figure 10).

Figure 10: Pipe Flow Legend

![clip_image002[1] clip_image002[1]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEiY_enuMhI-aqumg4PLKcv_mlEZzHNJHnFZXSAFuGVPOhJbG9cAHETLSbe2TOP2X-AGBDX6-hzkmN_dgLrrUGsEkP3vs2lV5WnwAit0J3slmvyiY3FIZh8_P44eUEHE_LIvDMuVmAtG31M/?imgmax=800)

Hii I am Vikram Lunge working in Building automation system last six month,but i am interested in revit MEP 3D modeling, but i don't have any idea about MEP can u guide me...is it useful for feature scope ....

ReplyDeletePlease do needfull....

Thank you...

I'm looking for a button to push for the autosizing stuff, where is it? lol

ReplyDeleteI'm having an issue regarding fixture units with some families I created. The families are created correctly with preloaded fixture unit parameters. I have a lavatory family that has 2 types: public and private. The public lav water FUs are greater than those of the private lav. When I connect multiple fixtures together and tag the pipe, I get the correct fixture units, but once I change the family type of a public lav to a private lav, the pipe fixture units and tag don't automatically update. They don't update until I break a section of the water piping and reconnect. Any ideas as how to fix this issue?

ReplyDeletehow can I set the formulas in the families for input data (es. 100gpm) and 10 (different) terminals from 10 to 20gpm?

ReplyDelete(heater or VAV)flow in = 100gpm (calculated configuration) => formulas?

(terminals) flow out = 10÷20gpm each (preset configuration) => formulas?

thanks

Air conditioners are essential for comfortable living during the summer months. Cold air is dry air - that is air without moisture.

ReplyDeleteSplit Units

Really impressive blog you got here. Thanks for posting...

ReplyDeleteHeating and Cooling Mississauga

Really impressive blog you got here. Thanks for posting...

ReplyDeleteHeating and Cooling Toronto

Really nice and definitely it will be useful for BIM User's. Kindly keep update like this.

ReplyDeletefor more details and work link belwo:MEP F modelling in UK

ReplyDeleteThank you for sharing the information MEP F modelling in UK

ReplyDeleteThanks for sharing.

ReplyDeleteMEP F modelling

شركات تنظيف فلل بالدمام

ReplyDeleteشركات تنظيف شقق بالدمام

شركات تنظيف مجالس بالدمام

شركات تسليك مجاري بالدمام

شركات مكافحة حشرات بالدمام

Looking for https://coraductcleaning.com Best Duct Cleaning in Toronto, must visit Cora.

ReplyDelete