I was able to make an information schedule for checking Duct Sizes, Flows, Friction and Velocity.

I set up my schedule starting with a Duct Schedule.

Example

Fields:

I added fields for System Name, Size, Flow, Friction and Velocity.

Filter:

I filtered by System Name – does not contain – Default. This is so any ducts that are on a default system do not show up in the schedule. (ex. Return boot ducts which are all the same size.)

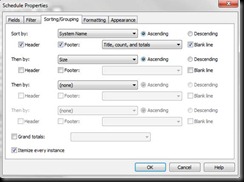

Sorting/Grouping:

“Sort by” is set to System Name. I checked Header, Footer and Blank Line (I named my systems with the equipment type mark). “Then by” is set to size so the ducts are organized by size.

Formatting:

I did two conditional formats; One for Friction and one for Velocity.

Friction is set to greater than or equal to. I set the value to 0.10 in-wg/100ft which is the number the engineer told me to use to size duct under 1000CFM.

Velocity is set to greater than or equal to. I set the value to 1200 FPM which is the number the engineer told me to use to size duct over 1000 CFM.

Here are some examples of the schedule:

If the Friction is greater than or equal to 0.01 in-wg/100ft it will be highlighted in red.

Example:

Here is an example where a duct may be improperly sized.

You can click on the row where it’s located and select “highlight in model”. I usually have a 3D view open when doing this so it goes to the exact location of the duct.

Highlight the row

Select Highlight in Model

I usually have a 3D view open so that I can see exactly where the duct is.

Wow..thanks a lot for this..should speed up the design process, and help watch the model better. Thanks a bunch..great blog by the way.

ReplyDeleteThanks for the great post.It really gives me an insight on this topic.

ReplyDeletethank u for posting MEP F modelling

ReplyDeleteThanks for sharing MEP F modelling in USA

ReplyDeleteThanks for sharing.

ReplyDeleteMEP F modelling

Thanks for sharing. very interesting.

ReplyDeleteMEP F modelling in UK